Links:

Because beauty should never come at the price of your health.

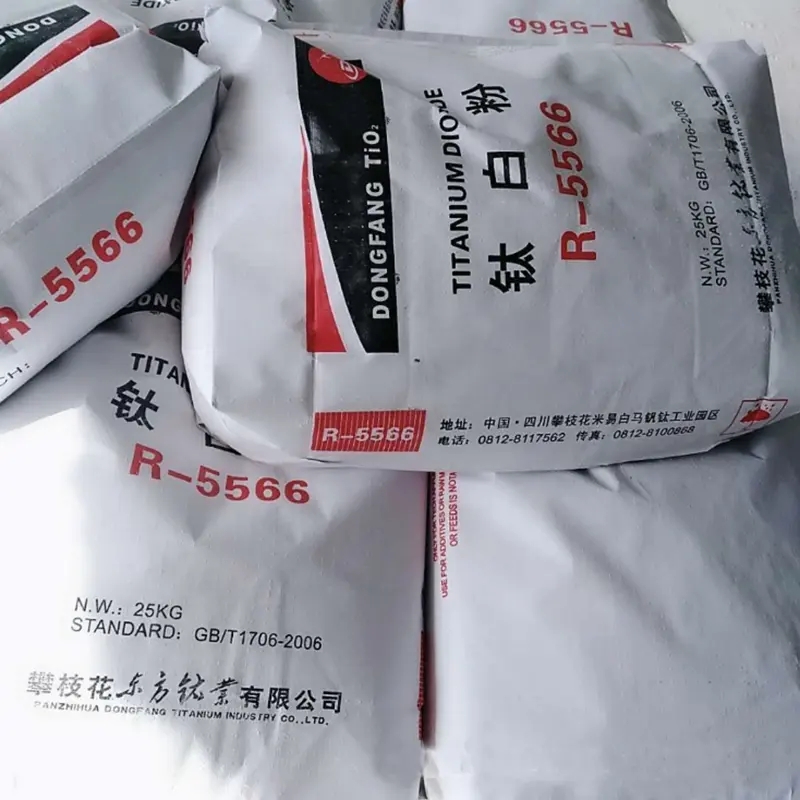

The global titanium dioxide (TiO2) market, with a production capacity of around 10 million metric tons per year, is a testament to the significance of these factories. Ranging from small-scale operations to large, state-of-the-art facilities, they form an integral part of the chemical industry's landscape, particularly in countries like China, the United States, and Russia, where production is most concentrated. Furthermore, the gravimetric analysis factory plays a crucial role in quality control and assuranceIt offers several advantages in various applications. Its excellent opacity and brightness make it a popular choice in the production of paints, coatings, and printing inks, providing a cost-effective alternative to titanium dioxide. Lithopone's chemical stability enhances its durability in outdoor environments, making it suitable for outdoor coatings. Additionally, its low reactivity and compatibility with other pigments contribute to its versatility. Beyond coatings, lithopone finds utility in plastics, rubber, and paper industries. Overall, its multifaceted advantages and broad applications underscore this compound's significance in diverse industrial sectors.

6. What happens next?

However, China's dominance in rutile titanium dioxide manufacturing is not without challenges china rutiletitanium dioxide manufacturer. Environmental concerns have become a major issue in recent years, as the industry's rapid expansion has put pressure on natural resources and ecosystems. To address these challenges, Chinese authorities have implemented stricter environmental regulations and encouraged the adoption of cleaner production technologies. These efforts have helped to improve the industry's environmental performance and ensure sustainable growth.

china rutiletitanium dioxide manufacturer. Environmental concerns have become a major issue in recent years, as the industry's rapid expansion has put pressure on natural resources and ecosystems. To address these challenges, Chinese authorities have implemented stricter environmental regulations and encouraged the adoption of cleaner production technologies. These efforts have helped to improve the industry's environmental performance and ensure sustainable growth. Rutiles Tio2 Titanium Dioxide Lomon R-895 Coating Grade Industrial Use

One of the reasons why our lithopone products are highly sought after is because of their superior quality. Our lithopone B301 and B311 are made from the finest raw materials, ensuring that they meet the highest industry standards. This means that you can trust our products to deliver excellent performance and long-lasting results.

Because of their small size, nanoparticles may have unique physical and chemical properties. These properties may cause them to interact with living systems differently than larger materials with the same chemical composition (also known as bulk materials).

Titanium is a metal element found naturally in the environment. When it's exposed to oxygen in the air, it forms titanium oxides that are contained in many minerals, sands, soils, and dusts.

≤14

2. Hazard identification The MSDS should outline any potential hazards associated with the handling and use of lithopone. This includes information on the physical and chemical properties of the product, as well as any potential health hazards or environmental risks.

One of the key strengths of O2Ti is its commitment to innovation. The company constantly invests in research and development to stay ahead of the curve and deliver cutting-edge solutions to its customers. This has led to the development of several patented technologies that are now being used by manufacturers around the world. The production process at a TiO2 concrete factory begins with the careful sourcing of high-quality raw materials. Titanium dioxide is extracted from mineral sources like rutile and ilmenite through a complex series of chemical reactions. Simultaneously, other ingredients such as cement, aggregates, and water are prepared for the concrete mixture. Among industry leaders, certain names continually surface due to their unwavering dedication to excellence. These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards

These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards

These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards best pigment rutile titanium dioxide manufacturers. Their rutile titanium dioxide pigments are known for their consistent color, unparalleled opacity, and optimal dispersion characteristics, ensuring seamless integration into various substrates. In conclusion, rutile and anatase titanium dioxide are essential components in many industries and are constantly evolving due to ongoing research and technological advancements. Suppliers who can adapt to these changes and meet the growing demand for high-quality titanium dioxide will be well-positioned for long-term success in this dynamic market.

best pigment rutile titanium dioxide manufacturers. Their rutile titanium dioxide pigments are known for their consistent color, unparalleled opacity, and optimal dispersion characteristics, ensuring seamless integration into various substrates. In conclusion, rutile and anatase titanium dioxide are essential components in many industries and are constantly evolving due to ongoing research and technological advancements. Suppliers who can adapt to these changes and meet the growing demand for high-quality titanium dioxide will be well-positioned for long-term success in this dynamic market. One of the key responsibilities of titanium dioxide manufacturers is to produce high-quality products that meet the stringent requirements of their customers. This involves carefully sourcing raw materials, employing efficient production processes, and conducting rigorous quality control measures to ensure that the final product meets the necessary specifications.

This ensures that the final product meets the highest standards of purity and quality This ensures that the final product meets the highest standards of purity and quality

This ensures that the final product meets the highest standards of purity and quality This ensures that the final product meets the highest standards of purity and quality